The method of Six Sigma in project management (PM) determines a specific set of practices and business strategies that enable organizations to enhance the quality of their products/services and to exploit process improvement opportunities. The definition and implementation of Six Sigma method within business environment let establish the DMAIC cycle and follow best practices of quality control and assurance. Many companies today prefer this method to traditional project management, regardless of the failure rate that ranges from 35% to 75% of all Lean and Six Sigma projects. Furthermore, those companies need to consider the critical success factors and find out how to perform their improvement programmes using the popular approach.

The method of Six Sigma in project management (PM) determines a specific set of practices and business strategies that enable organizations to enhance the quality of their products/services and to exploit process improvement opportunities. The definition and implementation of Six Sigma method within business environment let establish the DMAIC cycle and follow best practices of quality control and assurance. Many companies today prefer this method to traditional project management, regardless of the failure rate that ranges from 35% to 75% of all Lean and Six Sigma projects. Furthermore, those companies need to consider the critical success factors and find out how to perform their improvement programmes using the popular approach.

What is the Definition of Six Sigma Method?

The gurus, who developed the fundamentals and best practices of quality management (such as William Deming, Philip Crosby, Joseph Juran, and many others), provided Six Sigma definition and made detailed prescriptions for successful quality improvement programmes. Initially, Sig Sigma defines that 99.99966% of the products manufactured are expected to be free of defects (no more than 3.4 defects per million or, in practical terms, zero defects). The methodology was originally implemented by Motorola in early 80s, when the corporation wanted to formulate a strategy which could minimize the risk of project failure in production process. Since that time, Six Sigma cycle has been adopted in other business processes, and today it is widely used by businesses to identify and eliminate the causes of lower process performance and to minimize process variation.

Higher Process Performance through Six Sigma Change

Everything that a business organization carries out can be regarded as a process (or part of a process). The purpose of Six Sigma method is, provide an improvement mechanism to change a process or its component for higher effectiveness and efficiency. The approach involves that business processes (production, selling, negotiating, and the like) need to be characterized against average performance and variation, so that decision makers will use these measures to figure out how the processes can be performed in an optimal way (equal or greater than the average performance level) and at the expected value (with minimal variation). Then the processes’ outcomes are expected to be free of defects and errors.

Six Sigma Definition

Many processes in business are prone to being affected by special causes that undermine the overall process performance and break client expectations. The method of Six Sigma in project management determines a set of best practices to change a process for better through eliminating defects and errors. Its ultimate goal is to achieve the expected performance and minimize the variability of a process to ensure this process delivers an outcome that meets client specifications and financial projections. Project-oriented organizations consider it the philosophy of making change to a process through statistical quality control and performance improvement. This philosophy involves combining various specialists into project groups for in-depth expert analysis and better decision making.

Six Sigma can be defined as a project management methodology that determines how to improve the quality of products or services produced by a business organization through the removal of defects and errors. The method involves developing a business management strategy which is then implemented by groups of people within the same organization who are experts in various knowledge areas. Each expert group carries out the allocated job in an effort to complete the entire improvement project and meet the financial milestones.

The Focus and Key Elements of Six Sigma Method

The method is about ensuring continuous improvement to eliminate process waste and inefficiency, thereby increasing client satisfaction and improving employee performance. In this regard, the primary focus of Six Sigma in project management can be described by these three elements:

- Client

- Process

- Personnel

Client

The “Client” element defines expected quality levels to be reached by the project. A person or organization assigned to the role of Project Client will require greater process performance, reliability, on-time delivery, competitiveness, and more. Six Sigma approach focuses on delivering the expected results that ensure customer satisfaction.

Process

The “Process” element defines a set of metrics and measures for evaluating Six Sigma cycle processes. Quality will be the major parameter against which to look at the project from the client’s perspective. Alternatively, while the focus is placed on process quality, the project can be measured and evaluated from the outside-in (or in terms of the client’s needs).

Personnel

The “Personnel” element involves that improvements can be achieved only if the company involves all employees in Six Sigma project management. Then the personnel will be provided with incentives and opportunities to focus on improving their talents and abilities, thereby enhancing individual performance and satisfying the customer. It is important to method success that each participant involved in quality improvement implementation has a well-defined role with measurable targets. This element is often regarded as one of the critical success factors.

Roadmap for Six Sigma in Project Management

Managing a Six Sigma project involves following a certain sequence of steps or a life-cycle that breaks down a process to be improved into components with the expectation of quality enhancement within each. The project aims to improve all process components, so that the related financial and social impact will be addressed. It considers all possible value-added steps that could provide the highest possible reduction in process variation.

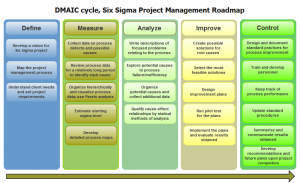

DMAIC Cycle

The life-cycle of Six Sigma project is defined in the sequence “DMAIC” – Define, Measure, Analyze, Improve and Control. The following picture explores the DMAIC cycle in detail.

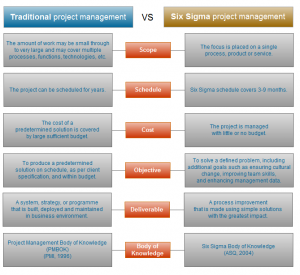

Traditional Project Management vs Six Sigma Cycle

Best practices of traditional project management are widely used and followed throughout all sectors and all types of business, as they have been among the most pivotal managerial tools for years. Meanwhile, Six Sigma method is becoming more and more popular among companies that tend to find a solution that combines a robust quality improvement methodology with a sound project management process.

In truth, traditional PM and Six Sigma cycle have many similarities, for example: both focus on identifying problem areas, developing feasible solutions, allocating resources, setting priorities, others. However, there are distinct differences. Below on the picture you can see the comparison by such parameters as Scope, Schedule, Cost, Objective, Deliverables, Body of Knowledge.

Critical Success Factors of Six Sigma Project

In Lean and Six Sigma project management, a critical success factor (the acronym “CSF“) represents a definite characteristic, variable, or condition which directly and significantly impacts the sustainable process development and viability of an improvement project. Any project activity impacted by CSFs requires immediate attention and excellence in implementation in order to ensure the achievement of one or more intended objectives. Typically, Six Sigma project is managed under 3-7 success factors.

For example, one of the CSFs in call center might be, implementing a client support system in a way that reduces dropped calls. Another example: for a financial institution that wants to improve loan application process CSF might be, designing an online loan application form that reduces errors at any stage of the process, including Submitting, Reviewing and Approving.

The following four groups of factors make direct impact to the success of Lean and Six Sigma cycle:

- Leadership

- Team

- Top management support

- Setup stage

1. Leadership-Related Success Factors

In 2005, the Project Management Institute (PMI) undertook a review of how leadership styles of traditional project managers impact success rate and whether leadership can be regarded as a critical success factor. Their research explored the traits of a good leader and also revealed that leadership in its “pure” sense has a direct impact to project success. Meanwhile, PMI also noted that the project managers have to overcome some authority barriers to their leadership approaches in order to influence success rate. The research findings are also relevant to Lean and Six Sigma success.

Authority Gap

In projects (especially complex ones) managed under Six Sigma method, the project leaders often face a dilemma called “authority gap“. This dilemma is that while a project leader is authorized to direct and coordinate team members, these team members are acquired and assigned by a functional manager who is not often familiar with the approaches to be employed within Six Sigma project environments. The leader does not select team members, and this fact creates a gap in leadership and authority.

In order to fill this gap and have full authority over team selection and leadership, leaders need to try the following for successful Lean and Six Sigma:

- Use formal agreements that authorize the leader to take full control over HR for the duration of the project life-cycle.

- Be open and oriented to human relations, giving the team credit for good work and letting them know the significance of their contribution to the project.

- Leverage a range of effective motivational techniques and remain observant of each employee’s contribution.

The Traits of a Successful Six Sigma Leader

A good leader provides effective control and coordination for teams, ensuring success of collaborative effort. The following determines the seven traits of a successful Six Sigma leader:

- The ability to identify, define and solve problem

- Orientation to results

- Enthusiasm and energy

- Self-confidence

- Effective communications “builder”

- The ability to negotiate and address issues

- Perspective

2. Team-Related Success Factors

In traditional project management, selection of the right team which is properly developed and motivated is critical to success achievement. By ensuring adequate orientation and training of team members, the project manager can prevent failures during the setup stage and subsequent stages in the life-cycle. Furthermore, team training for complex projects is much preferable to learning on the job.

In the practice of successful Six Sigma process improvement, it is preferable that the project leader is trained to green belt or black belt level. Team members should undergo Six Sigma training and develop their skills prior to commencing improvement work. Besides, the following three factors will enhance success rate:

Superordinate Goals

Managing Six Sigma project involves selection and coordination of cross-functional teams which must focus on the same superordinate goals. Such goals are urgent and important to all team members and require the groups to work jointly in order to complete those goals and deliver the project as expected.

Team Rules and Procedures

The success factor determines authoritative statements and fixed, step-by-step sequence of activities to which group members need to adhere in order to ensure team efficiency and effectiveness. Team rules and procedures enhance the level of group collaboration and lead to greater goal achievement.

Physical Proximity

Team members who are located in the same office area earn more chances for success at work. Co-location or physical proximity enables frequent and conducive interactions between the employees, leading to better implementation of quality improvements. This factor is highly relevant to Lean and Six Sigma cross-functional teams.

3. Top Management Support as a Critical Success Factor

The literature and research findings on Six Sigma project management prove that top management support is prominent as a critical success factor. This CSF impacts the level of many project variables, including resource availability, organizational structure, team skills, stakeholder involvement, etc. By garnering support from the highest-ranking executives and sponsors, the project manager gets the ability to make decisions that extend project scope, involve greater budgets, and increase authority. At the same time, the manager takes greater responsibility for Six Sigma success.

Six Sigma Programme Management

Large empirical studies conducted by the American Society for Quality (ASQ) confirm that sustained success of Six Sigma in project management largely depends upon whether an organization establishes programme management to align its ongoing projects with the business objectives. In this regard, Six Sigma programme management serves as a high-ranking support tool that enables senior managers and sponsors to impact project success strategically. This tool lets combine smaller parallel projects into larger programmes which are managed under single risk management practices, change control processes, and quality assurance procedures. Then the projects are more likely to be delivered on schedule, within budget and to client specification.

Top Management Commitment

As a CSF, top management support entails the following commitments for senior executives:

- Establishing and serving on a committee responsible for quality control and process improvement

- Formulating and setting up quality policies and programme objectives

- Providing resources and personnel training opportunities

- Providing guidance, leadership and advice

- Overseeing Six Sigma success achievement at all levels

4. Success Factors Related to Project Setup

According to recent research conducted by iSixSigma analysts, there is a set of success factors that relate to the project setup characteristics. By project setup they regard a one-time, non-recurring stage of Six Sigma process life-cycle during which the project is “getting ready” for implementation. This stage determines the boundaries between planning and estimation on one side and execution and delivery on the other. When the project setup stage finishes, the team can proceed with performing the work according to the plan.

At the setup stage, the following factors determine success of Six Sigma management:

Project Vision

An inspiring vision of what the project is to achieve substantially impacts success rate, because vision statement serves as a clear guide for the team to focus on right course of action. The vision should be formulated by the sponsor in close collaboration with the appointed project leader and a stakeholder reference group.

Resource Availability

An organization gets more chances for success when it has all necessary resources available to begin a quality improvement process. Resource availability is identified as a root cause of failure in any type of project, including process improvements.

Team Motivation

Without stimulated desire and energy in people involved in project there is little chance of success. Motivation ensures continuous interesting in and commitment to project. Motivating a team means manipulating both conscious and unconscious factors to intensify the team’s need for greater performance, provide an incentive or reward value of the goals accomplished, and consider the expectations of each individual.

Activity Schedule Design

The urgency of the work that must be done defines Six Sigma success, and a well-designed and accurately estimated schedule determines optimal durations for project activities.

Communication

The lack of effective communication in between the team and target stakeholders at the setup stage will cause poor change control and misunderstandings, which in turn result in failed collaboration and knowledge exchange.